As a company that engages in manufacturing sector, Sritex ensures that have been accordance with sustainability principles in conducting its activities namely the balance between “triple bottom line” which is people, profit, planet. The Company measures the success of its business based on corporate social responsibility, its responsibility on environment and benefit. A developing model is not only creating financial profit but also social responsibility.

Sritex recorded USD485.945 for the distribution of economic value on the implementation of whole CSR activities during 2018.

Initiative in implementing the environment has been giving a contribution on some efforts to make Sritex as a sustainable business textile. The Company is committed to keeping and improving the performance in maintaining environment for creating long-term environmental friendly textile industry and maintaining business reputation in global market.In 2018, the Company has applied the policies in maintaining the environment, among others.

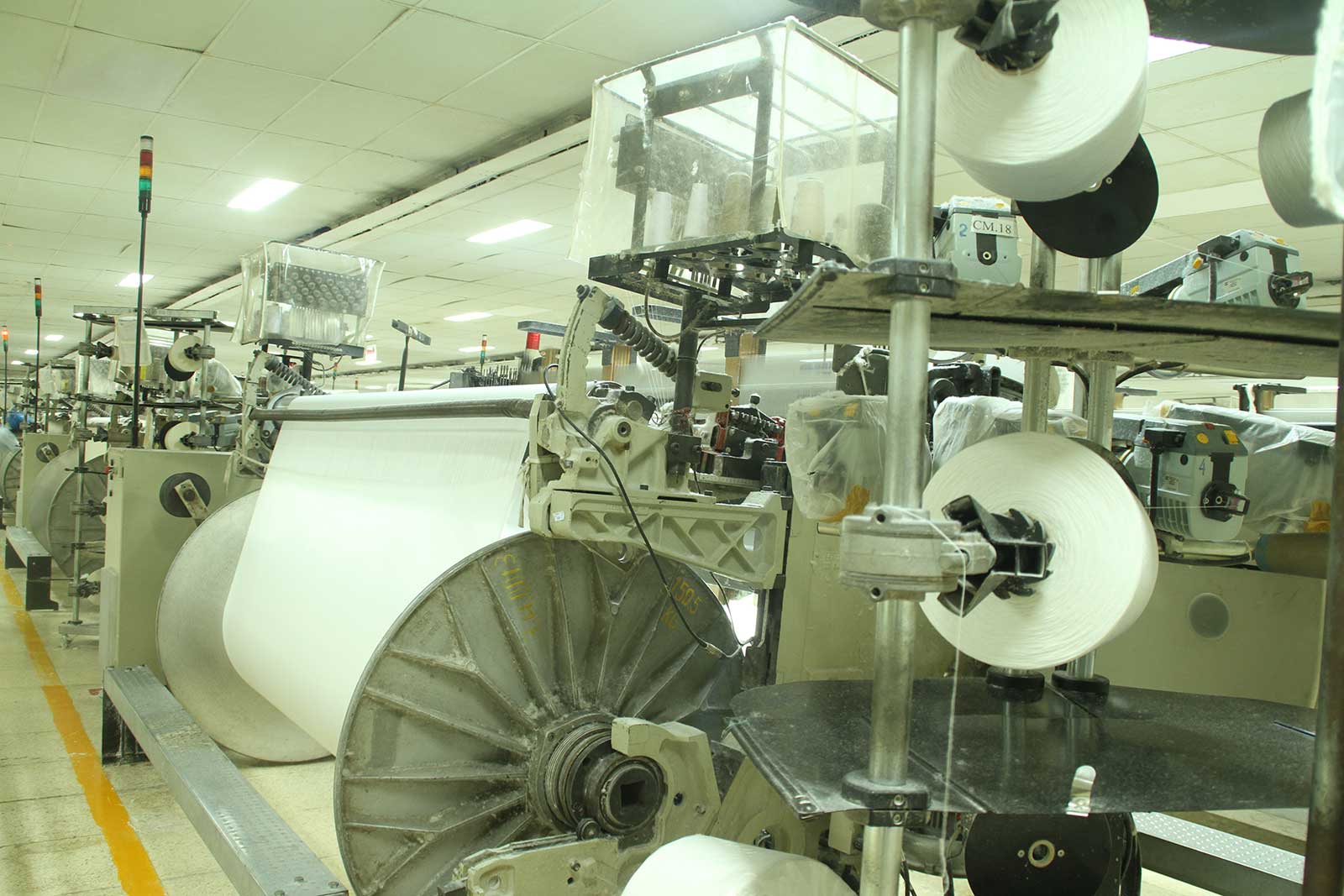

Sritex’s business operations have been vertically integrated to help the Company to have broader control in its production process. In this case, the Company can determine the use of raw materials that can be renewed to produce products that are more environmental friendly.

Since 2018, the use of renewable raw materials have reached 70% of the total raw materials used.

The energy management system has been being implemented by the Company to control energy consumption referring to the ISO5001 standard. This means that the energy management system has been oriented with the Green Industry. In 2018 the Company succeeded in reducing the number of energy intensity to be 0.143 Gjoule/Piece of clothing product, which has dropped from the intensity of energy usage in the previous year.

REDUCE EMISSIONS

The company also fully supports the commitment of the Government of Indonesia to participate in reducing GHG emissions by 29%. Sritex’s contribution in reducing emissions figures is demonstrated through the planned energy efficiency policy. The Company’s energy efficiency program also contributed to the reduction in emissions intensity by 90% when compared to the previous year.

It cannot be denied that the business operations of the textile industry have an impact in the form of waste for both liquid waste and solid waste. In managing liquid waste, the Company has WTPP / IPAL to treat wastewater from the rest of the production process. In total during 2018, WTPP / IPAL in the Company has processed 100% of the water used for the production process and has been flowed back into the river with proper quality standards. For solid waste, some are reused and discharged into landfills.

In the side of Environment certification, the Company has had certification, among others:

• ISO14001:2015

• Proper from Minister of Environment

• Audit NATO (Bundeswehr Jerman certification)